World Exposition in

The Yugoslav Pavilion

Sometime in autumn of 1956 I received a call from Mr. Vjenceslav

Richter, an architect in

During the first meeting I was shown their model of the pavilion that

took me by surprise for sure. I had to ask who suggested me to work out the

structural design for an extraordinary pavilion. They obviously have been

asking around the more experienced colleagues but nobody wanted to risk his

reputation or just to waste time for a not executable structure at first glance

at least. Looking at the rather intriguing model I felt some weird desire to

take this task although I envisaged instantly that the solution would ask for a

non-classic static design procedure.

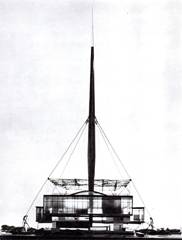

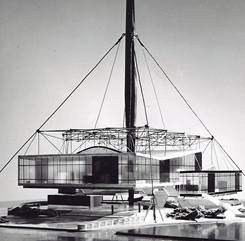

The model photos

from the competition prospectus DIKSI 2 by Vjenceslav Richer and Pavel Weber

for the Yugoslav Pavilion on Brussels World Fair 1958. Left the model total

view and a closer corner view at right.

The proposed structure would have to consider rather complicated forms

of deformation and deflection including considerable pre-stressing forces in

four main cables. On a rectangular space truss hang the pavilion cubicle with

floor dimensions 32m x 40m. The pavilion box like that should not represent any

particular structural problem despite its unconventional form. The deformation

of hanger rods should be kept as small as possible not to influence the box

structure hanging on the space truss above. The real problem presented the

fixation of the rectangular space truss at its four corners onto the four main

cables. The deflection of these cables should have the most significant setback

in the whole design. Apparently the four cables should have to be designed for

a rather large strain – probably subjected to a pre-stressed force.

First task was to make reasonable and stiff enough structure for the

pavilion cubicle in considering a symmetrical position of hanger rods in two

concentric parallelograms. The position of rods dictated the form of space

parallelogram truss on that the pavilion box hangs. Thus one could calculate

the pavilion and space truss dead load leading to the most decisive point of

the overall design. I had consulted a few elder colleagues at the Faculty of

Civil Engineering in

The four main cables would be strained by the space truss at four points

about half way of the cable’s total length of say 65m each. Part of the

structure’s vertical deformation would depend upon the vertical loads dead and

live ones. The live loads could be applied non-symmetrically to the structure’s

two main axes of symmetry that resulted in considerable horizontal (lateral)

movements. The wind load would add its part to the additional lateral movements

thus increasing the overall instability of system attached to cables only. This

was for me the first time that was confronted to the second level of elastic

deformation in an elastic system. This kind of deformation is the result of

position change of structure’s center of gravity bringing the system out of its

stability under a particular load arrangement.

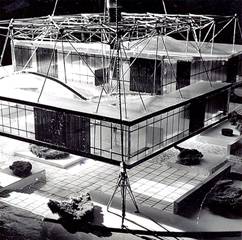

Photograph

of model corner close up

Photograph of model front elevation

Three staircases perpendicular to each other (3-point fixation) would

prevent the pavilion to rotate around its vertical axis. The rotational

stability was one of the crucial points to be considered in particular because

of the 4-point fixation on cables holding on the central column. The live load

of visitors moving indiscriminately on the pavilion two floors could result in

certain vertical as well as horizontal displacements. I believed that the

installation of adequate hydraulic absorbers at the bottom of each staircase

could smooth out any of such displacements also those caused by a quick live

load dislocation or some sudden one say in case of panic.

The central column was double conically pointed having a maximum

diameter of say 1m and a total height of some 85m. The 4 cables fixed to a ring

at 45m above the ground kept the central column firmly in its position. The

whole structure should be made of steel and manufactured in

By end of February 1957 I have completed the preliminary structural

design that included a rough calculation of quantities for the building

materials for the pavilion. My companions have agreed to a new arrangement of

the pavilion interior to comply with the redesigned structure compared to the

prized model. Soon the three of us were invited to visit the Commissariat in

Around a long table sat about a dozen persons and the session started

with Commissary’s introduction asking about progress of the pavilion design.

The architect Richter informed that we achieved an agreement about the pavilion

form and other arrangements of arts. He asked me to refer about the proposed

structural design as this is the main objective of this meeting. At first I

went on with my explanations quite well but when it came to the 4 cables the

unrest rose in the audience with some loud objections from a few elder persons.

One of them was the professor for steel structures design on the University in

By my estimate one needed a cable of say 90 - 100mm diameter probably

not available on the market. However similar sized cables had been rescued from

the cable bridge over

The new design request did not present any major problem for me as the

columns had to be placed more or less at the same position like the one of

original hanging rods. It was agreed to rearrange the décor panels to enable

hiding the vertical truss stiffener between two adjacent panels. These

stiffeners provided the horizontal stability to the pavilion when subjected to

horizontal loads. The engineers of the appointed steel construction company

from Slavonski Brod asked for a minimum height of 900mm for the main beams of

steel profiles that was more on economic than on safe side. The architect rejected

this request allowing max. 600mm that I had calculated as needed for a box type

cross sections. One of contractor’s engineers was my colleague who cleverly

understood that the pavilion’s design is not necessarily to be an economic one.

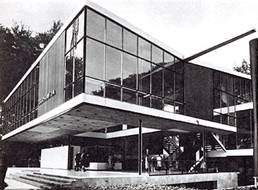

The EXPO was a rare occasion to show the engineers’ capability to follow

esthetic aspects where the costs did not matter. The contractor left

Richter almost fainted when he noticed the columns’ dimension made of

steel profiles. They looked really massive and ugly as made of large “I” steel

joists only. I intervened again and proposed a column’s cross section that

would be looking much thinner in the open space. The column had to be made in a

cross like form out of 4 angle 100mm steel angle profiles welded together

corner to corner. The narrow front of some 22mm width would be painted bright

off-white where as the inner angles’ areas would be painted with black color.

From far one would get an impression that the pavilion stands on petite

“needles” where as the wider frontages would merge into the surrounding darkness.

Richter was very pleased with my understanding of the esthetics. The contractor

had to “grind his teeth” again but was happy with more steel weight and works

to be paid for that was not his matter at all.

A few months passed and I got an order for a travel to

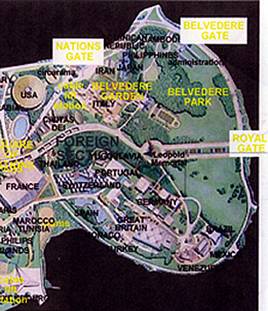

The eastern part

copied out from the Expo Map is the Yugoslav pavilion (above the

in the FOREIGN SECTION

with three gates. At right is “ATOMIUM” the landmark of EXPO 1958.

The next day I walked over the EXPO grounds where many pavilions were in

various stages of construction. I saw that the lowest sphere of the “Atomium”

is erected already and passed by the huge plot of the

On the next two Belgian engineers appeared introducing themselves as the

quality inspectors on the EXPO. They expressed their concern regarding the

quantity of cement used in the concrete for foundations that well bellow the

permissible in Belgian standards. I tried to explain my reasons based upon

strength test results. We agreed that contractor could pour the concrete to

finish that foundation now. However I had to visit the Head office in town for

further consultation before continuing the concrete work. The next day I went

to the town and found the Bureau of Survey and Quality Control (BSQC) that

turned out to be a private company. I met there several more elderly colleagues

and after an amicable conversation my argumentation was accepted to be a right

one. The qualities of supplied gravel and cement were excellent enabling a considerable

cost saving that was essential considering that all works on EXPO are of

temporary character only.

The established good contact with the BSQC would turn out as important

in about a year. For the rest of my stay I had an easy stand controlling the

concrete pouring and the completion of a dozen of foundations. On evenings I

took the tramway to

On one such occasion I visited the

Throughout the sojourn I had to economize with my daily traveling

allowance that was US$10 per day including the rail ticket to and for

After we parted from the pub I had badly needed a walk before going to

bed. I noticed Mrs. Rosenberg walking her dog at the far end of street and

walked over to join them. The next morning I could not remember what we were

talking about last night. Madame greeted me in as usual in French saying: “Last

night you spoke in French so well to me. In future you should not talk to me in

German anymore, mon chere ami!” I was so perplexed I continued on in French

instantly doing so all through my stay here. When I came to the site Mr.

Obradović who was the Contractor’s chief engineer informed us about the

good news for the May 1. The Yugoslav embassy has booked a bus for all workers

for a one day trip to the coast on that national holiday in

Contractor’s workers

on a day trip to Knokke (at left) and during lunch break near Brugge right.

Embassy’s representative

at centre (dark glasses) and Mr. Obradovic second at right in back row.

The day was perfect for a trip starting from

At left the Lion

monument on a hill near

I visited the town of

Several months passed and I did not hear from

Richter anything not even to mention that I did not get a reimbursement for my

contribution in his project. Suddenly early in January 1958 Richter called me

to visit him most urgently. When I arrived to his office he produced a strange

looking object or form waving it in front of my nose and said: “You will have

to design this “object” to be the column in front of Yugoslav pavilion!”

Further he said this form reminds him of Calder’s Movables and that it would be

a sensation on the EXPO. At first moment I was flabbergasted seeing three

umbrella’s spoke bent making a bow each strung and fixed on a tendon of thin

wire. Each bow was positioned at an angle of 120 degrees to each other and the

ends were fixed to the sinew at the third of its length. By Jove, it proved to

be a stiff “structure” and a very elastic one to stand straight upright too.

I just could not believe that this “form” could

be constructed into a column like structure of 6 bows (one each for

With joined efforts we were able to compute the

first three bows only. The deformability of this system asked for the

accounting of elastic first and second displacements that had to be evaluated

step by step. At those times we used slide rules and mechanical calculators –

lucky if you had one driven by electricity. I called on Richter to inform him

about rather disappointing outcome of our tryouts. It did not make him happy at

all as the Committee’s request was too adamant that the pavilion must get a

striking column to be seen from afar. Richter was much upset and forced me to

find the solution to create that “column” at what ever price of. Then like a

strike of lightning I got the idea – to tiny bars holding the sinew at fixation

point to the inner two bow’s pipes. Later I added a turnbuckle to each enabling

correction on the sinew’s alignment to a vertical. These bars should be painted

black that would make them almost invisible once the “column” is erected in

front of the pavilion.

Richter liked this idea and urged me to start

with the necessary computations and drafting of the working drawings. In the

meantime he found a steel workshop in

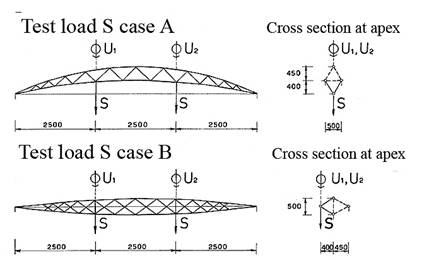

The bow and the

sinew fixed to by two bars had to be subjected to two test load cases A & B

My mentors complimented my idea of the two bars

fixing the sinew at each bow’s third point allowing keeping it straight. This

solution made the statical calculation much simpler so it could be completed

for all 6 bows within two weeks. The calculation resulted in a great reduction

of steel profiles thus of the total weight and of the exposed surface to wind

load too. The necessary sinew steel profile became small so we had to choose

diameters of 20, 25 and 30mm of the solid steel rods. Later the sinew was to be

painted in dark grey making its round profile hardly visible against the

background. A colleague suggested help to produce the working drawings as he

was working for the plant producing the seamless pipes in Sisak.

The following weeks were extremely hectic for me

and I spent most of the time at the steel manufacturing workshop. I had to

supervise the shaping and welding of the many various steel profiles to be

formed to a bow. The first made bow subjected to load tests at the Institute

for Testing of Materials and Structures of the Civil Engineering Faculty where

I was employed as assistant. I arranged to test the bow subjected to lateral

loads at the two significant planes. The test’s results were rather promising

and proved that the design was correct and safe for its use. We barely

succeeded with the trial assembling in

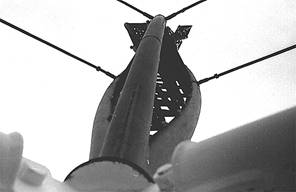

In meantime the shallow pool and a Y-shaped

slender bridge over it were completed according my design. The column and the pear-shaped

support stood on a tripod of 3m height and placed over the “Y” corner of bridge

with the sinew exactly over it. The column consisted of 6 bows 7,5m that lowest

of sinew was fixed through the top of a pear-shaped latticed support of 8,5m

height. The later one stood on a tripod and was kept in position by 3 pairs of

tendons of round steel rods of 22mm diameter. The tendon upper end was fitted

to the connection to the lowest bow. The lower ends of tendons were fastened to

3 anchor blocks of that the foundations were hidden under the pool. The total

height was 45,5m as measured from the bridge top up to the peak of column. The

column itself stirred up quite a curiosity and some anxiety and the rather

slender bridge too. The overall design was my great “secret” that I wanted to

reveal to the Belgian supervisors only.

At left the lifting

hook holds the temporary assembled column and a worker checks column’s bearing

joint on the “pear” support being the lowest structure’s element

Despite my limited traveling allowance we

managed we take the trip together so my wife would attend the opening ceremony

with me. However we had left our daughter at Liljana’s family in

At left the column

being assembled on floor its top bow is the nearest one and start up of lifting

at right.

When the tripod was erected a mobile crane

lifted up the “pear” support on top of it. With the three pairs of tendons that

had double-screw connections at each of end one was able to fix the “pear”

firmly in the vertical position. One achieved a not-rotating stable “pear” by

staining the tendons double-screw connection to the anchor block. Everything

was ready for the column to be put on its pear-like support. In the meantime

one assembled the six bows on the ground by fixing the sinews with pairs of

cross-bars that had a turnbuckle on each bar. Thus we achieved an almost

straight sinew line in adjusting the turnbuckles prior the column to be lifted

up.

Soon after lunch break another mobile crane with

a long boom arrived to lift the assembled column onto the “pear” support. First

the short cut lowest third of sinew rod Ř30mm was carefully put through the

opening on “pear” top. The column lower bow end was turned so that it passed through

the “window” that was an opening left in one of the “pear” latticed side. The

crane slowly lowered the column until the bow end plate sat firmly on the

“pear” internal tripod support. A short Ř30mm rod was pulled in through the

hole on support and its top end fixed with a turnbuckle to the short cut sinew

end. Then the short rod bottom end was strained firmly using a double-screw

joint too.

These procedures were completed within say two

hours when I instructed the crane driver to release from the hook a lifting

snare that fell to the ground. For the first time a complete column stood there

swaying slightly. The trial erection in

At left lifting and

placing of the “pear” element and at left two stages of column lifting and

moving in.

There was a lot of admiration for the erection

crew coming from all present in final stages of completing the Yugoslav

pavilion. The prompt column assembling within a few days was for me the

greatest achievement and something extraordinary in view of the short time we had

on disposal. The two supervisors of BSQC arrived when the column was up already

and were rather astonished its “crazy” form. Later next day I would get the

invitation from their office to give a lecture about my design explaining the

column structural complexity.

The next morning I had to explain some

structural details to the security officer who was worried about the tiny rods

(Ř22mm) holding the “pear” support and the column going up swinging erratically

under the wind. I told the officer that according my calculation the column

peak would move for about 1cm at a wind speed of 1km/hour. That would mean that

at wind speed of 50km/hour the peak would move for say 50cm. Then we stood on

the bridge and looked up to the column and I was so astonished about the peak

movements in an elliptic form that made me almost queasy. The officer was

astounded too and looking at the 3 pairs of tendons asked: “Comrade Engineer,

what would happen if one of these tiny rods gets cut maliciously?” On my first

impulse I suggested to replace it instantly. Then even more worried he asked

about if both rods of one tendon pair get ruined by explosive. I answered

straightforwardly: “Get far away from the column fast! It will collapse for

sure!” He left me alone most worried and deeply concerned with the security

measures. He left irritated thinking about how to organize the necessary

controls instantly.

I passed around the buzzing pavilion with the

interior decorators and artists looking after their pieces of arts being

properly placed within the pavilion area. I wanted to make out the progress on

the Yugoslav restaurant that construction started belatedly. Our idea was to

invite Mrs. Rosenberg’s son Roger and his wife for a dinner on opening day

tomorrow. Thus we wanted to thank our hostess for giving Liljana the

accommodation without any additional charge to me. Unfortunately the restaurant

was by far not ready so I decided see the Commissar who acted like director of

the Pavilion. On my way I met one of the BSQC supervisors who was looking after

me and happily handed me a letter of invitation from his office. By this

invitation the Bureau kindly asked if I could held a lecture to the Belgium

Engineering Society about “the column” now standing firmly in front of Yugoslav

pavilion.

At left the view

upwards from “pear” hold by pairs of tendons up to column tip. The erection

crew from

and the author (left at

centre) standing on the bridge below tripod on right picture.

I went straightforwardly to the Commissar to

explain the invitation and how it would be a good opportunity to publicize this

unique project. I asked him for a few days of allowance extension that was to

be beyond fixed time of my stay on the EXPO. He was rather busy and nervous

about the short time left for all works to be completed on time so he bluntly

refused my request. He said nervously: “Look, I have so many of these artists

who mingle around not being able to finish their job in time. All of them want

more daily allowances and I cannot spend more than my allowed budget means.” I

must have looked at him with some distrust and misapprehension so he continued

in appeasing tune: “Look, comrade engineer, you accomplished your task well and

on point in time. You deserve to go home in good content what you did for your

country.” I thanked him with a rather dour smile and left the site not to

return to it anymore.

The views of the

Yugoslav pavilion after the opening – at left the south elevation and the

entrance at right.

On my way to my quarter I had to pass the

Hungarian pavilion where I found out that their restaurant was open. On my

first thought I went in a found the maitre d’ and reserved a table for 4

persons for the next evening. On the EXPO opening day of April 17 there was a

free entrance after the opening ceremony would be over that would save me

expense for entrance tickets too. Liljana was somehow surprised about early

return but she accepted to accompany me to the city where I had to the Bureau

regarding their invitation. My wife did not like the

Northern access to

the pavilion at left (Portuguese pavilion in background) and the column total

view right

We did not attend the opening ceremony and spent

the day in sightseeing the city centre. That evening Roger Rosenberg and his

pretty young wife arrived and drove in their car to the main entrance from

where it was the shortest way to the Hungarian restaurant. Table was ready for

us and after an aperitif of peach brandy we ordered meals to be Hungarian

specialties. The dinner passed in perfect mood except for me counting the costs

so that the end sum would not get over budgeted amount I had with me. When the

waiter brought the dessert menu I told my wife in Croatian to choose the

cheapest cake on the menu. Out of blue sky the waiter said in Croatian: “Take

the Dobosh tart. It’s very good and I won’t charge more than you can pay!” This

was the surprise of the day! The waiter came from

The pavilions

colored pictures show Yugoslav pavilion at left and Hungarian one at right

Roger suggested he would take to the city and show

us something brand new in

~ ~ ~ ~ ~

Epilogue

The architect Vjenceslav Richter honored my contribution

and work on the project of Yugoslav pavilion rather late in 1958 after all. The

amount he paid somehow meager and not adequate for the time I have spent on

this project. However it helped us to finance the move to our first own flat in

Several years later Richter published an article

about the Yugoslav pavilion on the EXPO 1958 in

Early in 1959 Roger Rosenberg sent us the

birthday card informing that his wife gave birth to a boy. Their son is the

“result” of the dinner in Hungarian restaurant in April 1958. What a pleasing

result it was!

The Yugoslav pavilion at EXPO 1958 World Fair

was renowned for its futuristic design. Now it is the best conserved of most

EXPO buildings and is still in use as a classroom in Saint Paulus

College at

Copyright © Zvonko

Springer, Anif (

Photographs and colored enclosures:

1. Monograph of Vjenceslav

Richter, Editor Vera Horvat-Pintarić; Printed

and

Copyright by GRAFIČKI ZAVOD HRVATSKE,

2. B&W photographs from Zvonko Springer

records.

3. Colored inserts are from following URLs:

http://users.pandora.be/nevi/expomap/index.htm

,

http://users.skynet.be/rentfarm/expo58/viewmaster/index.htm

.